- StoreProjects

- Free Plans and Projects

- Furniture Projects

- Jigs And Fixtures Projects

- Shop Projects

- SketchUp Models

- Shop Storage

- Workbenches

- Free Woodworking Downloads From Lee Valley

TechniquesToolsVideos- Premium Streaming Video Site

- Experts Guide to Gluing & Clamping Wood

- Mastering Built-In Furniture

- Simple Live-Edge Slab Table

- CNC – Designed for Woodworkers

- Milling Your Own Lumber

- Advanced Bandsaw Techniques

- I Can Do That! – Simple Woodworking Projects

- Woodwright’s Shop with Roy Underhill

- Tricks of the Trade

BlogOur content is meticulously curated through independent research, testing, reviews, and AI-driven recommendations, all designed to present you with the finest product choices. When you make a purchase through our links, it could result in us earning a commission.The Best Wire Connectors for Safely Joining Electrical Wires

Last updated: 1 Jul 2024

Wire connectors are devices used to join two or more electrical wires together securely. They are designed to ensure a reliable electrical connection while also protecting against electrical faults, such as short circuits or loose connections. Wire connectors come in various types and sizes, each suited for different purposes and wire gauges.

In our research, we looked at the adhesive type, waterproof rating, durability, and material type(s) of all the wire connectors on our list. Because of its high-quality tinned copper material, adhesive-lined heat shrink tubing, and user-friendly installation, the Wirefy Wire Connector is at the top of our list!

- Best Overall: Wirefy Wire Connector Shop Now ➔

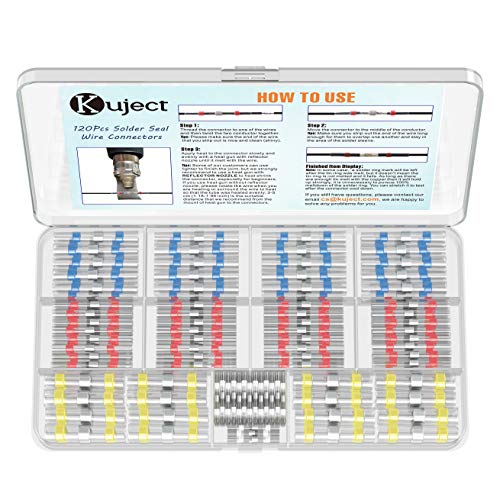

- Easiest to Use: Kuject Wire Connector Shop Now ➔

- Most Variety of Sizes: Nilight Wire Connector Shop Now ➔

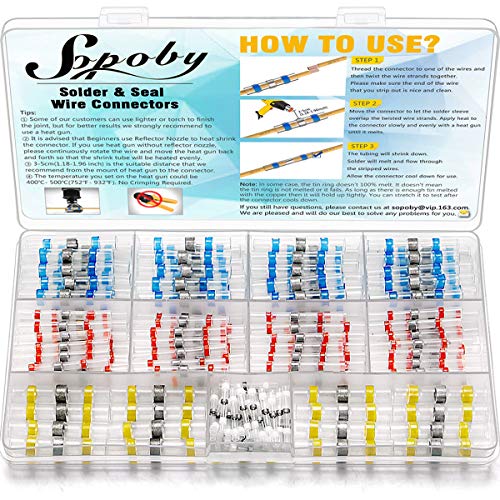

- Great Value: Sopoby Wire Connector Shop Now ➔

- Most Durable: Brightfour Wire Connector Shop Now ➔

View all Contents- The Best Wire Connector Buying Guide

- Wire Connectors FAQ

- What type of wire connectors should I use?

- Are there any safety measures to consider when using wire connectors?

- Can I use any wire connector for 90-degree connections?

- How do I get a waterproof seal when using connectors?

- Are there wire connectors specifically designed for electrical usage in cars or boats?

- Why should I get a pre-filled connector?

- Related Reviews

The Best Wire Connectors

Best Overall

If you’re looking for a reliable solution for your DIY home wiring project, look no further than the Wirefy Wire Connectors. Made from premium quality tinned copper, these wire connectors have an adhesive lined inside to help you make a secure electrical connection every time. These heat-activated connectors are extremely easy to use and ensure protection against the elements to prevent potential electrical hazards. Even better, the thick copper barrels offer a seamless connection and the adhesive ensures that the wires stay put, even under heavy pressure.

They also don’t need high temperatures to cure — you can easily install them with a lighter, a hot gun, or even a hair dryer for an airtight seal. You can get them in different sizes and colors to fit multiple gauges and color code wires to organize the electrical connection for quick identification. With their marine-grade build, voltage drop protection, and affordable price tag, these wire connectors earn the top spot on the list.

Pros

- Strong adhesive offers an airtight seal

- Thick barrel for stronger crimp

- Very durable

Cons

- Shrink sleeve burns quickly

Easiest to Use

The Kuject Wire Connectors are your go-to choice if you’re looking for a dependable waterproof option. First of all, these marine-grade connectors come in nine different sizes to fit your buying needs. But, what makes these butt connectors different from others is that you don’t need to crimp them — they can be joined simply by heating them with a hot gun or a lighter. To offer maximum protection against the elements, they also come with two adhesive rings that smoothly metals on heating to create an airtight seal.

Additionally, these connectors are made to last a lifetime and won’t crack or tear apart even under pressure or heavy weights. The package also includes a low-temperature soldering sleeve, allowing you to use them right out of the box. Because they are thoughtfully engineered to offer a high success rate, these wire connectors won’t shrink the tubing before the solder ring for a solid wire connection every time.

Pros

- Dual-walled design provides better protection

- Adhesive lined for a strong connection

- Waterproof

Cons

- Not ideal for heavy wiring

Most Variety of Sizes

The Nilight Wire Connectors are a great pick for tackling all types of wiring projects. This set features self-stripping electrical T-tap connectors to make it quick and easy to tap into existing wires. The kit also includes male quick disconnects that are suitable for a wide range of projects such as marine, automotive, scientific, or home wiring. With their thick tinned copper contacts, these connectors provide maximum conductivity, preventing voltage drops and short circuits.

The T-tap connector housing is designed to lock on the wire securely, and it stays put once you’ve snapped it shut, providing a safe and secure connection. You don’t have to worry about these connectors sliding out, either, as the male disconnects are made using nylon to lock them tightly in place. The easy-to-use wire connectors are made with quality materials and are designed to last, making them the perfect choice for any DIY or commercial wiring project.

Pros

- Great conductivity

- Comes in a wide variety of sizes and colors

- Easy to connect and disconnect

Cons

- May feel a bit flimsy

Great Value

The Sopoby Wire Connectors offer superior water protection and abrasion resistance, making them ideal to use both indoors and outdoors. Due to their double wall design and hot melt adhesive inside, these connectors are made to securely keep wires in place and last years of use. The heat-shrink tubing provides additional insulation while also providing improved pullout strength. Even better, the heat-activated adhesive makes them resistant to stretch and durable enough to withstand vibrations.

These connectors’ tin barrels ensure increased current flow, too, so you don’t have to worry about voltage drops and wiring failures. Even better, they are easy to use and provide reliable connections every time — all you need to do is simply insert the stripped wire into the ring terminal and crimp them with a heat source to create an airtight seal.

Pros

- Color-coded for quick identification

- Weather-resistant

- Resistant to melting

Cons

- Adhesive takes longer to melt

Most Durable

From connecting and bundling different types of wires to creating insulating seals, Brightfour’s Wire Connectors are an excellent choice. Featuring a unique, innovative copper clasp connection design, these tap connectors are far superior to traditional wiretaps, eliminating the need to peel, strip, cut, solder, or weld wires. One pack includes 12 wire connectors of different sizes that are suitable for use with stranded and solid core electrical wires, allowing for a wide range of applications.

The connectors are small enough to be tucked away in nearly any space, making them practically invisible. Plus, their rock-solid connection ensures that your job is done right the first time, significantly reducing installation time. With a transparent surface and compact size, these connectors allow you to tack efficiently for the perfect seal. As the cherry on top, the housing of these wire connectors closing latches that work as a tray to keep the wires from sliding or pulling out.

Pros

- Very durable

- Durable and flame-retardant

- Made from high-quality materials

Cons

- Can be difficult for beginners to use

The Best Wire Connector Buying Guide

Whether you’re a DIYer who wants to organize your house’s electrical connections or a professional electrician that needs to stock up on wire connectors, choosing the right pack can be difficult. To help you find the right type of wire connectors for your needs, we’ve put together this comprehensive guide with all the essential information. So, keep reading to make an informed decision.

Things to Consider Before Buying a Wire Connector

Durability

Look for connectors with strong construction and high-quality materials that are designed to hold up against wear and tear over time. In particular, you should examine how the connections are made and how well they stay secure when tightened. If you’re looking for a durable option, look for wire connectors that come with metal components and reinforced plastic housing for increased longevity.

Compatibility

As different wires require different sizes and styles of connectors, ensure that the connectors work with the type of wires they’re intended to be used on. If you aren’t sure about the type of connectors to get, consult a professional or carefully read the packaging to make sure you pick the right ones for your needs.

Electrical contact

Check that the connector has enough electrical contact points to ensure a secure connection between the two wires. This is especially important when dealing with sensitive electronic components, where even a slight disconnect could lead to malfunctioning or loss of power. So, always make sure there is a good connection between all pins for improved conductivity to avoid any issues down the line.

Size

Pick connectors that are sized appropriately for the type of wire being used, as wiring that is too large or small can cause installation problems or even voltage drops and short circuits. Generally, you should get a large connector to use on your trailer wires, while a compact connector will do the job of connecting wires around your home’s lighting or your car’s engine bay. That said, size can vary depending on the brand and type of connector you are looking at, so make sure to double-check before buying a specific type.

Electrical rating

Make sure that the connectors have a high enough electrical rating for the application to prevent them from overheating or becoming a fire hazard. You should also pay special attention to the ampere rating when determining the appropriate electrical rating for your project. This information can usually be found on the packaging or by consulting with a professional electrician if needed.

UL-listing/approved

The connectors you choose must have been tested and certified by a trusted source, such as Underwriters Laboratories. This will help ensure that your purchase meets all relevant safety standards and is suitable for use in your project.

Anti-corrosion coating

Select connectors with an anti-corrosion coating, which will help keep them looking good over time and protect against rusting or other damage caused by moisture or salt air. In addition, it can help protect against short circuits due to corrosion buildup on contacts over time.

Wire Connectors FAQ

What type of wire connectors should I use?

The type of wire connectors that you should use depends on the nature of your wiring project, the size and type of wires you’re connecting, and whether the connection is in a dry or wet environment.

- Generally, twist-on connectors and crimp connectors are the most commonly used types of wire connectors. Twist-on connectors typically provide a quick and reliable connection without any special tools.

- Crimp connectors are generally used in more permanent installations as they create a strong connection that can withstand vibration and extreme temperatures.

- Heat-shrink connectors also provide added protection from moisture and electrical interference.

Are there any safety measures to consider when using wire connectors?

Yes, it’s always important to make sure that you follow all electrical codes when using any type of wiring device. Additionally, wearing protective eyewear while working with wires is always a good idea to prevent accidents due to sparks or debris flying around.

Can I use any wire connector for 90-degree connections?

No, not all wire connectors can be used in 90-degree connections, as some require a straight connection to provide a secure connection between the two wires. Depending on your needs and the type of wires you want to attach, there are specialized 90-degree angle connectors available that have been designed specifically for these types of connections.

How do I get a waterproof seal when using connectors?

To achieve a waterproof seal when using a wire connector, you must ensure that it has been properly installed according to the manufacturer’s specifications. The wire connector should then be covered with an approved silicone sealant or another waterproofing material to prevent water from entering exposed areas or causing damage over time due to corrosion or rusting.

Are there wire connectors specifically designed for electrical usage in cars or boats?

Yes, there are automotive-grade and marine-grade wire connectors that have been designed specifically with these types of applications in mind. They can help ensure improved electrical performance, even in harsh environments where traditional types of wire connections may not be reliable due to continuous exposure to the elements (such as salt water).

Why should I get a pre-filled connector?

The main advantage of using pre-filled (or preloaded) connectors is that they provide an easy way to establish an electrical connection. These connectors don’t strip back the insulation from each strand to insert them into the terminal end before crimping down, which saves time and reduces errors if done incorrectly.

They are ideal for open circuits that may lead to voltage drops or fires if not corrected quickly enough after being identified during an inspection.

Article Contributors

Read More About Popular Woodworking Reviews Team HereThe Popular Woodworking Review Team’s product reviews and comprehensive guides are here to help you select the best gear and tools to efficiently complete top-quality woodworking projects.

Popular Woodworking is reader-supported: When you buy through links on our site, we may earn an affiliate commission. Artificial Intelligence (large language models) may have been used in the research and creation of the content.

Questions about product testing or a specific articles should be sent to aimperiapt@gmail.com